Air preheater & Gas-Gas Heater Solutions

Contact

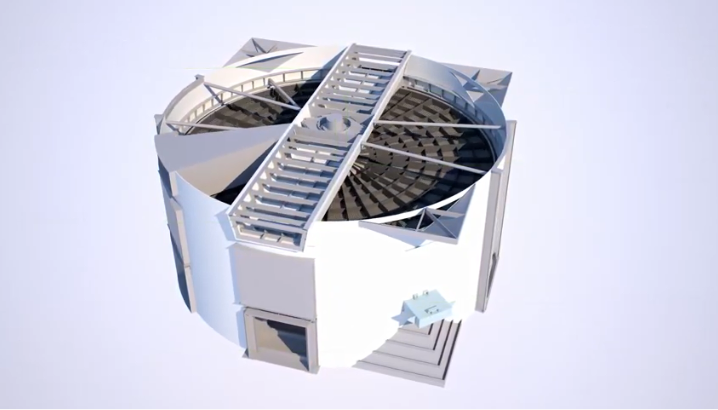

Advantages of LJUNGSTROM air preheaters

- Flexible design options

- Efficient sealing systems

- Advanced heating elements and baskets

- Reduced erection costs

Advantages of LJUNGSTROM gas-gas preheaters

- Advanced heat transfer

- High efficiency sealing systems

- Cleanability & maintenance

- Easy installation

PARTS - SERVICES & SOLUTIONS

- Enhancements & Upgrades

- Certified Ljungstrom® parts and components

- Inspections Certified Ljungstrom® parts and components

- Efficient Sealing System

- Customized Maintenance Plan

- Emergency Services

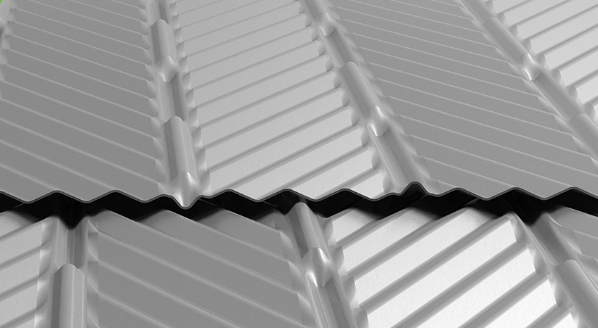

HEATING ELEMENTS

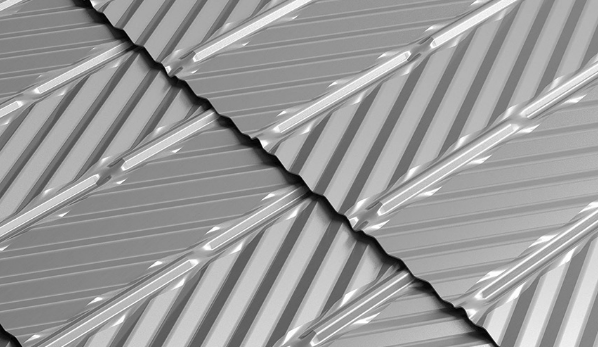

DN8 -ADVANCED HEATING ELEMENTS

- Increased thermal efficiency for equal depth in conventional designs

- Lower operating costs for the same thermal efficiency

- Lower pressure drops for the same thermal efficiency

- Even flow distribution

- Even plant upgrades without affecting your bearing or drive units

- Extended equipment life & significant long-term savings

TF4 - FULLY CLOSED CHANNEL ELEMENTS

- Over 10% increased thermal performance for the same depth of element layer

- 3% improvement in thermal performance for equal pressure drop

- Capable of withstanding 25% higher sootblowing pressures

- A lighter and more efficient surface to reduce rotating weight and prolong bearing and drive unit life

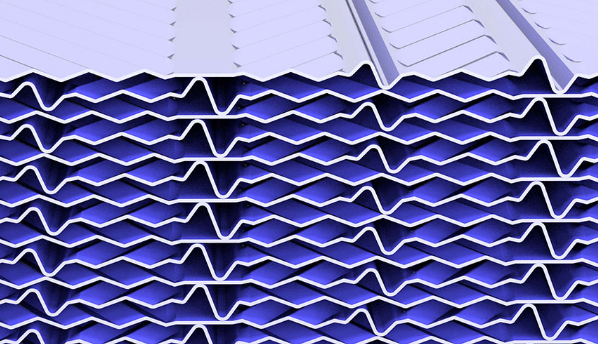

PROTEC ENAMEL ELEMENTS

- Resistant to corrosion, for extended product life

- High chemical resistance against aggressive flue gas components

- No need for pretreatment other than degreasing of the steel by rinsing it with hot water containing detergents

- Resistant to temperatures up to 400 degrees Celsius

- Superior and homogenous bubble structure

- High elasticity and adhesion onto the profiled elements to allow for sufficient packing pressure

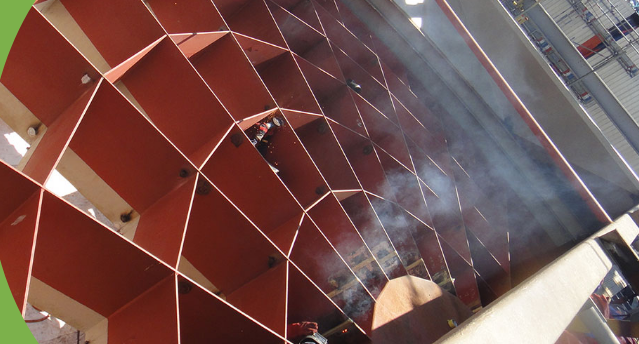

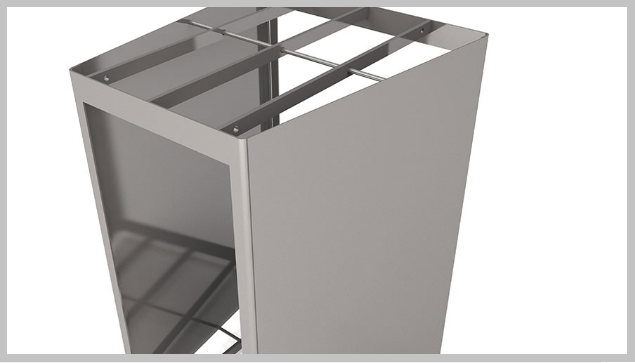

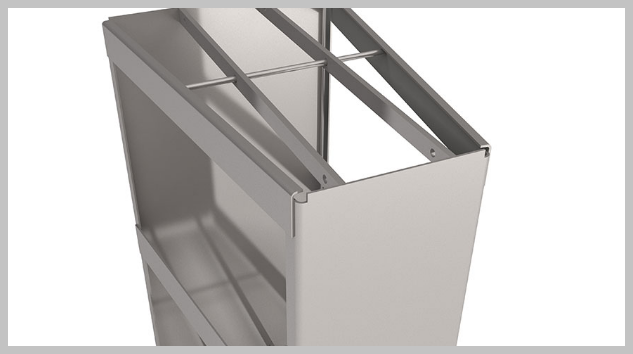

BASKETS

LJUNGSTRÖM THERMAL GUARD BASKETS

- Maximize your air preheater's thermal performance

- Minimize flow bypass

- Easily replace your heat transfer surfaces when the need arises

- Optimize the performance of your plant and save on costs in the short and long-term

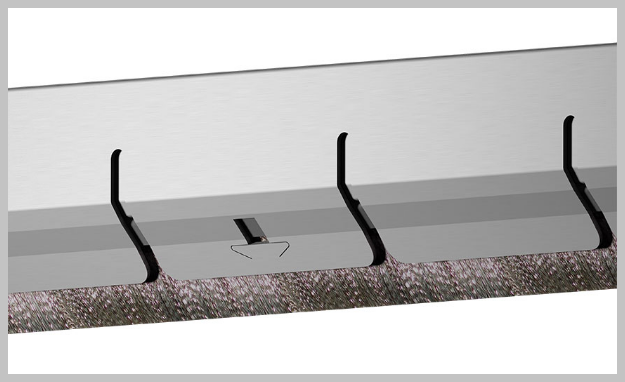

EDGE GUARD BASKETS

- Prolong element life by minimizing the effects of soot-blowing damage to element sheets

- Improve your bottom line thanks to the cost-effective design of Edge Guard™ basket

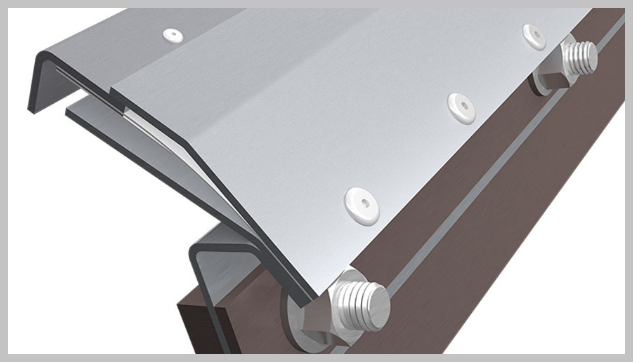

SEALS

OPTIFLEX RADIAL SEALS

- OptiFlex Radial Seals flexible leaf accommodates pressure differentials and encourages deflection away from the sealing surface

- Reduced cyclic pressures also lead to a longer operating life and help avoid the premature failure of the flexible leaf portion

- Utilize the latest generation of our flexible seal technology to significantly lower your hot end air to gas radial leakage in your Ljungström® air preheater

ROTABRUSH ADAPTIVE BRUSH SEALS

- SAVE ON FUEL - Reduced fuel consumption and impoved plant efficiency due to adequately sealed air preheater

- REDUCE YOUR CO2 EMISSIONS - Using the RotaBrush Adaptive Brush Seals means less coal burning and less CO2 and other emissions

- LOWER YOUR FAN POWER - Reduced air preheater leakage leads to lowered fan power consumption, increasing the saleable MWs recovered.

- AVOID CAPACITY LOSS - Prevent fan limitations when MWs are needed.

- IMPROVE YOUR APC PERFORMANCE - Better control of your flue gas volumes and temperatures allowing better performance of air pollution control equipment.

- SAVE TIME AND MONEY - Ingenious replaceable seal cartridge system of RotaBrush™ Adaptive Brush Seals avoids the time-consuming and costly gap setting process

products

Shell and Tube Heat ExchangersPlate Heat ExchangersHeat Transfer Skids & StationsHydraulic Oil Coolers (Tubular)Hydraulic Oil Coolers (Turbo - Plate)Hydraulic Oil Coolers (Oil / Air Coolers) Exhaust Gas Heat ExchangersFully Stainless Steel Tubular Heat ExchangersStainless Steel Exhaust and Bypass DampersCharge Air Coolers & Jacket Water CoolersMarine Coolers & Header Tank CoolersPool Heat ExchangersAir preheater & Gas-Gas Heater Solutions